-

-

Most tools used in woodworking have a blade: The steel the blade is made out of needs to be of very high quality. It must flex enough not to break but still be hard enough to cut through very hard woods without dulling quickly.

-

Avoid Harbor Freight: there is a perception that HF tools are a good value. Inexpensive tools don’t have to be bad but Harbor Freights woodworking tools are terrible. Their steel is so soft that you won’t get through a single joint without needing to resharpen. Sharpening takes time, and that’s time you will be unable to focus on your builds.

-

Hunt down used tools: Hand tools don’t need to be brand new to function well, they need to be machined properly and made from quality materials. I will discuss what to look for in this guide. In my case 95% of my hand tools are used tools, most of the best functioning are over 100 years old.

-

-

-

Forget about brand loyalty: With the exception of a few outliers almost every company that has manufactured woodworking tools has made good and bad tools throughout the years. The details count, so thats what we will focus on.

-

Don't confuse monetary value with useful value: Just because something costs a lot doesn’t mean it's better at the job. Making something pretty usually doesn’t make it work any better.

-

There are volumes written on this subject. This is meant to be a somewhat brief look, or a pocket guide to get you making as quickly as possible.

-

-

-

Sharpening kit: This is sort of a chicken or egg scenario, sharpening kit doesn’t work without tools, but a dull tool doesn’t work well either. At least if you have a sharpening kit you can make your kitchen knives useful again. There are a few methods, a lot of people start with the “scary sharp method”.

-

It's a good way to start cheap, but as you progress replacing sandpaper will become expensive. The good news is that the same equipment can be used later on with water stones for a legitimately razor sharp experience.

-

If I was going to buy a sharpening kit to use on tools that I was reconditioning I would start out with a DMT duosharp stone in coarse/fine and high grit sandpaper. The DMT stones don’t require flattening and can remove a lot of material quickly. The fine side of the stone can then be used as a flat base for the high grit sand papers.

-

The other part is a honing guide, they can be had for under $15.

-

A set of chisels: these are the most versatile tool in woodworking. Start with a 1/4”, a 3/8” and a 1/2” this will get you by on most things. Once you see how you are using your chisels you may want wider ones, or ones of a different design, so start small. ~$10-20/each

-

A square: There are many types of squares, a quality combination square is versatile and useful. Igaging makes a good 6” kit for around $35, buy used if possible. The woodworkers square pictured can be had at a yard sale for ~$5

-

A wooden mallet: Uses range from banging parts together to chisel work, all the way through tool adjustment and just making noise. You can buy a new one cheap, or better yet turn one on the lathe out of scrap wood (woodworkers are notorious for building tools, may as well start early!) $0-20

-

-

-

A hand plane: A number 4 tends to be the most versatile, these are a workhorse in the shop. Good used ones go for $15-20.

-

A block plane: A pocket size low angle block plane will get you forgiveness from many mistakes, and a good used one can be had for under $10.

-

A backsaw: Rigid backed saws are neccassary if you are going to be hand-cutting joinery or doing dovetails. Crown tools sells a brass backed Gent’s saw for ~$25. I don’t recommend buying saws used when first starting, sharpening them is difficult and requires special tools.

-

Card scrapers: If found used, great, if not consider going with the crown 375 & 377 kit with burnisher. Any piece of hardened steel works for a burnisher but if you don’t have any other tools to use this ends up being a good deal. You will save so much money on sandpaper and time that it is probably the single best investment in woodworking. $5-$30

-

Rough cut saw: Dewalt DWHT20545L (or similar) is >$20 and works well, consider this disposable, but should last for years.

-

Files: At least one Mill Bastard file, if your only going to have one get a fine Nicholson single cut with a handle, you need a handle for file work. You could also make your own handle on the lathe. Make sure you store the file(s) individually wrapped in paper or cloth, they chip easily! ~$6 + scrap for handle. Also a long term disposable item.

-

All in: I think you could reasonably be under $200, and none of this stuff should ever have to be replaced or outgrown. The picture shown are my tools I use them on just about every piece I build.

-

-

-

There are many shapes & sizes but to start with bench chisels are the most versatile. They will cut any type of joinery you could want and do it well. Good ones will last for generations.

-

Do a little research: I often buy these used wherever I find them, but ebay can also be an excellent source. There are some highly collectible tools out there and they will fetch top dollar if they are in good condition. They aren’t necessary, instead look for off brands.

-

Most chisels made before world war one (1914) are good quality, forged by hand and laminated steel. Sometimes a small difference in the makers mark can be the difference between an excellent piece of steel and a tool that will let you down.

-

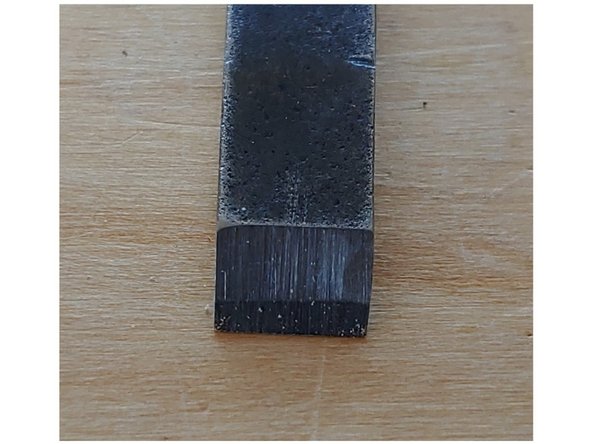

Don’t fear a little surface rust but deep pitting should be avoided. Deep pits on the back of a chisel will prevent you from being able to flatten it properly, if you see this pass and go on to the next one.

-

Socket chisels are the easiest to build a new handle for. You can create a basic one on a lathe in just a few minutes. Look for length: Longer chisels are easier to control, more blade length also means more sharpening life left. Stub (short) chisels have their place but aren’t necessary to start out.

-

Avoid bakelite or plastic handled chisels. Some are good but most aren't, additionally if the handle does get damaged it is VERY difficult to remove and replace. Most bakelite chisels date to an era when steel was low quality.

-

Don't worry if it isn’t sharp: make that sharpening kit start paying for itself. Buying chisels that are pre-sharpened comes with a mark-up in expense, you will have to learn to sharpen so why not start out with a dull chisel.

-

You can see on the middle blade that there is a fair bit of pitting. The pitting is far enough from the cutting edge that this is still an excellent and usable chisel. If it had been at, or within 1/2” of the bevel I would have passed on it. The pitting may be from age or from the initial forging; a lot of older tools were forged largely by hand

-

-

-

There are a lot of types of chisels available, they all do various jobs, some can do everything, but others are better at a certain thing, some are so specialized they cannot do certain things. We are going to look at 4 major categories. There are more.

-

Bench chisels are the jack of all trades, and you can do just about anything with them, I will focus on identifying bench chisels in this guide. Japanese chisels are not covered here, they are rare to find in the budget category.

-

From left to right a dovetail chisel, bench chisel, socket firmer chisel, and heavy mortising chisel The type of chisel refers to the profile of the blade and the construction. So a Socket Firmer chisel would be socket construction with a firmer blade.

-

Dovetail chisels are made for fine details and clearing out corners at >90°. They are too delicate to pry, chop mortises or do any heavy material removal. They are normally sharpened to a shallower angle (17-25°) to make them easier to use by hand

-

Bench chisels (Bevel Chisels) Have a similar top profile to a dovetail chisel with more steel for reinforcement. They can do it all, but won’t allow for ultra fine detail like others and are not suited to heavy chopping. They are also a little harder to get perfect mortises out of, but with a little practice they absolutely will do the job.

-

Firmer chisels are square top and bottom, but lighter than a mortising chisel. They are designed to square up corners and cut square joinery at a higher level of detail, they are excellent for cutting dados. They cannot cut joinery at angles less than 90°, and aren’t meant to take a huge amount of punishment.

-

Heavy mortising chisels are specialists in removing material quickly. Their large profile helps cut perfectly straight mortises. Looking at the diagram on the left you can see how much more effort is put into reinforcing them to take hammer blows than other types of chisels.

-

-

-

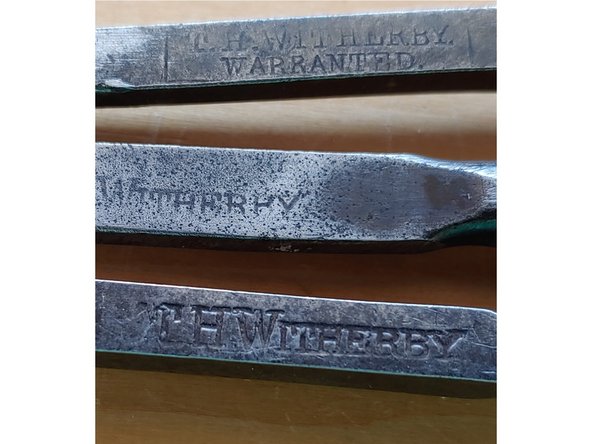

I found this listing on ebay this morning. These 3 chisels + a gouge are listed at $12.50 + $8.50 shipping. The photos are decent so lets look a little deeper. The listing is titled “Vintage Wood Chisels - Greenlee(3/4” & Concave), Keenkutter 3/8”, Withe 1/2”.

-

Having never heard of Withe before I looked at the photo of the marking, it clearly reads T.H. Withe, if you have looked at this guide in its entirety you will recognize that stamping as the T.H. Witherby stamping. This is actually great for us, because the tools are mislabeled: collectors won’t catch this on their radar and the price will stay low

-

They are all 3 bench type chisels so that part is right. The sharpening on the 3/8” looks a steep but is easily taken care of on the grinder, or leave it as is and double bevel the edge. The 3/4” is a little rough at the bevel as well but is easily taken care of. The 1/2” chisel is a little shorter than I like, but at this price that is forgivable.

-

The backs look pretty good, and there is only one handle; chances are that handle will actually work in any of the four tools, and if thats the case it also makes an excellent pattern for turning more on the lathe

-

Chances are pretty good you don’t need the gouge or know what to do with it at this point, you could sell it and recover most of your money, but I think the 3/8” chisel alone is worth the price so your really getting 3 chisels for the price of 1 plus a gouge to inspire learning. Conclusion: Buy it, good score.

-

-

-

Metallurgy is key to a quality chisel. Really good American chisels and high end Japanese chisels will have a layer of extremely hard high carbon steel laminated to a softer cast or mild steel. This gives the best possible edge retention, flex and impact resistance. It also drives the cost up immensely.

-

On the tool below I acid etched the blade so you can see this lamination. It may not be obvious if the tool you're looking at isn’t clean, and it will always be hard to see.

-

A few brands you can look for: Witherby, Sargent, Buck (Buck Bro’s), Eskilstuna, Union, H.G. Lea, Greenlee, Stanley (be careful buying Stanley, since they have made tools for so long and are very collectible it’s hard to tell exactly what you are getting. Quality varies from harbor freight level to top tier) There are lots more, this is an intro

-

The middle image was also on ebay this morning. I see no makers mark which is a bit of a concern because we have no way to date the piece, or know anything about its metallurgy.

-

The other concern is the “mushrooming” at the socket (Middle image). This chisel was clearly pounded on with a steel hammer with no handle attached to it; that is a lot of shock on the tool, and the mushrooming will take a grinder to remove. Conclusion: hard pass.

-

The lot to the right is listed at $31 + $20 shipping. At first it seems like a good deal for 14 chisels. Let's look a bit deeper. The bottom chisel has the unmistakable look of rusty chrome, this is an automatic pass, quality chisels are NEVER chromed. The next up is non-descript but if you look at the ferrule you can see its been hammered hard

-

The next two have no makers mark, next is a lathe gouge, then a skew, which could be really good but we have no info on it. Next is a tang constructed chisel with a badly checked handle which will also be a pass: too hard to repair. Two more carving gouges follow that, then another tang chisel with checked handle, and another gouge.

-

The top chisel looks like it would suite the need if we knew anything about it. Unfortunately that red stained handle is a dead giveaway: makers did this on low end chisels to cover up cheap or unsuitable wood. Conclusion: pass

-

-

-

Every size of plane has it’s own specialty but a jack plane will do almost all of it. If you haven't already read the tutorial on hand plane use take a look, there is more in depth knowledge on the usage.

-

Disassemble the tool and get a good look. Most shopkeepers won’t mind you taking a deeper look at a used tool, if you are gentle and ask permission first. Construction and machining are the most critical parts of a hand tool. It’s something that we as woodworkers can do very little with. Most don’t have the skill or tools to make major adjustments.

-

A broken knob or tote (the handles) aren’t a big deal, they are easy to make with just a file or rasp and a saw! But make sure the screws are there. The planes we are interested in use brass machine screws and they can be difficult or impossible to replace.

-

Should you avoid the kidney shaped holes in the top cap? A lot of guides will tell you to avoid these, the truth is Stanley used this design on a lot of planes for a lot of years. They aren't all bad and there is a lot more to the plane than that.

-

Avoid aluminum adjustment knobs: These are a tale-tell sign of a time where poor quality reigned, it also signifies the lowest end of most manufacturers lines. Look for brass or steel.

-

Check the sole: a grooved or plain sole doesn’t really make much of a difference, but heavy pitting or visible warping are to be avoided. Soles will almost always be scratched from use, thats alright.

-

Get the best tools your budget allows, quality tools work better and last. I truly believe I can’t afford cheap tools, I can’t afford to maintain them and I can’t afford to have them break when they are needed.

-

Avoid wooden soles: you will find planes with wooden bodies or wooden soles with metal bodies. Avoid these to start out with. They are wonderful in their own right, but the metal soled bodies are more straight forward to use.

-

-

-

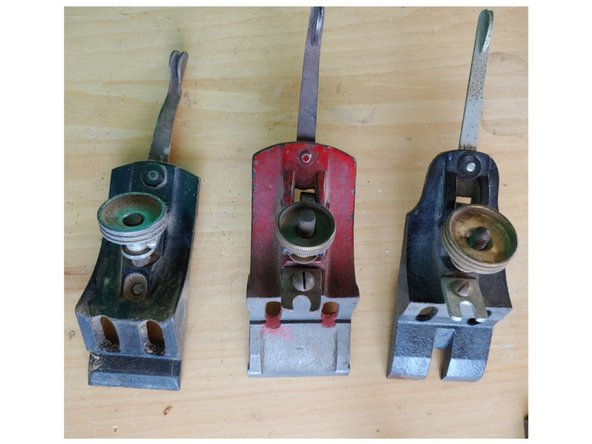

I will compare 3 planes here: They are all 3 made by Stanley at different times. I chose Stanley planes because most planes are modeled after them. They are not the only good brand!

-

Left: Stanley Handyman, in the 1950’s Stanley needed to come up with a way to compete with cheaper manufactures. These are the lowest end plane Stanley ever made, to be avoided. Middle: Stanley Record #4 1930’s or 40’s Right: Stanley Bailey #5 1908 or earlier

-

Upon examination of the casting and milling of the frog you can see the left plane has no millwork done, it is just as cast at the foundry. You can also see that the screws are a one piece part, where the other two are a heavy screw with a thick washer which is more mechanically sound.

-

The middle plane is fully surface milled but the casting is plain, note the difference in adjustment levers: the left plane’s adjustment lever is just one thin piece of stamped steel where the other two have a washer peened in place. The right hand plane has a more elaborate casting and all of the contact surfaces have been milled.

-

-

-

The plane above is currently listed at $22.50 on eBay, from the picture on the left we can see it is a Stanley Bailey. The top cap doesn’t have the Stanley name on it so if the top cap belongs to the plane it’s an older vintage, and since there is one patent number on the lever we know it is old, so we can assume it's from 1899-1902 which is good.

-

What we can see of the machining is that it is fully machined. The handles look to be in good condition without cracks. There is a little rust on the base, but its only surface rust. This plane looks like it could be bought and made to use with very little effort. I would absolutely get it and use it.

-

If you are going to buy used tools online don’t trust listings that have dark or hard to see photo’s, they are probably hiding something. If the photographer hasn’t disassembled the plane for the photo’s be leery.

-

If you find a good tool with a broken handle scoop it up! I replaced the tote on the third plane with a custom one that fits me really well and makes this plane a dream to use. I paid $9 for the plane and used some scrap for the tote. One day I will make a new knob to match the tote, but I use this thing a lot, it isn’t meant to be a show piece.

-

If you are buying used tools locally take your smart phone for research and a flat blade screwdriver (or Swiss army knife). Don’t worry about cosmetics, focus on functionality! once you decide you really like this stuff worry about buying shiny things.

-

Almost done!

Finish Line