Introduction

This guide can be used if you come across an empty roll of filament or if you need to change a roll of filament for whatever reason.

*Updated Firmware

- Updated Extruder Parts

Tools

Parts

No parts specified.

-

-

Dial

-

The nozzle must be hot to properly take out old filament / put in new filament.

-

Click once on the dial to open the menu.

-

Select Control

-

Select Temperature

-

Select Nozzle

-

Turn dial clockwise and select 200° by pressing in on the button.

-

You will be able to see that the temperature was set properly in the top left of the screen.

-

-

-

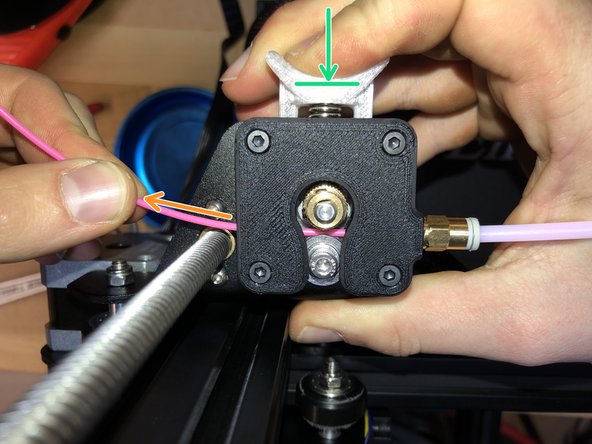

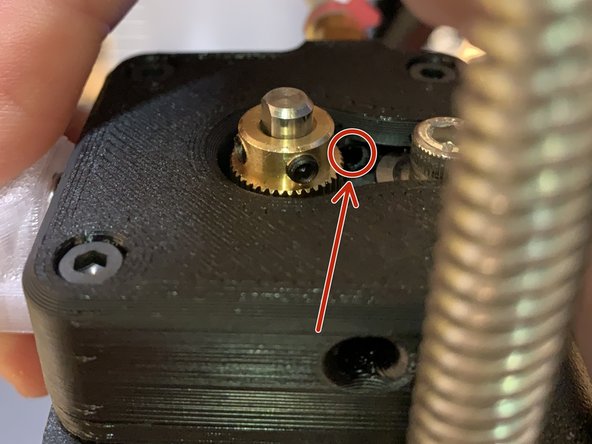

Push in on the spring-loaded extruder.

-

This will make space between the bearing and the extruder gear.

-

Pull filament out of printer from roll side.

-

Removing filament might require a decent amount of force at first to dislodge melted filament near nozzle.

-

-

-

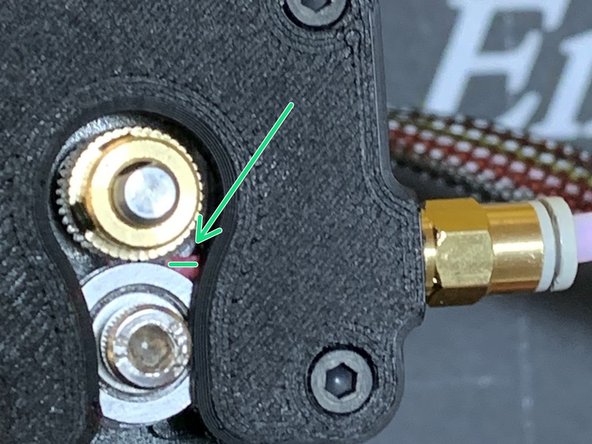

If the last role ran out during a print, there is likely still some leftover filament.

-

You can likely see this filament if you look close enough!!

-

We will want to remove this before inserting more.

-

-

-

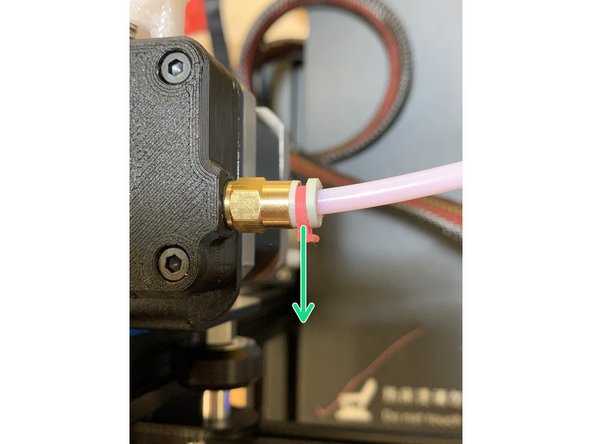

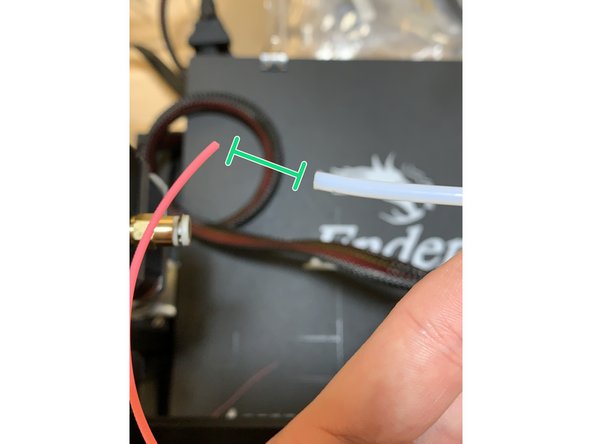

Remove clip from pneumatic fitting.

-

Press back evenly on pneumatic fitting AND...

-

If you are only pressing one side of the fitting, the tube will be extremely difficult to remove and could be ruined in the process.

-

Pull white tube out while fitting is pressed back.

-

-

-

Pull filament out of tube completely.

-

Removing filament might require a decent amount of force at first to dislodge melted filament near nozzle.

-

-

-

Remove filament role from all packaging.

-

Remove tape from filament.

-

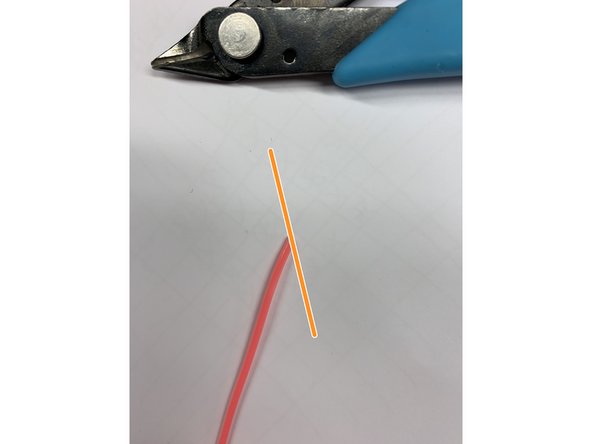

Cut end of new filament at an angle.

-

Bend filament so that the first few inches are straight.

-

This will make life a lot easier when attempting to insert.

-

If available, place filament on roll holder to make the coming steps easier.

-

-

-

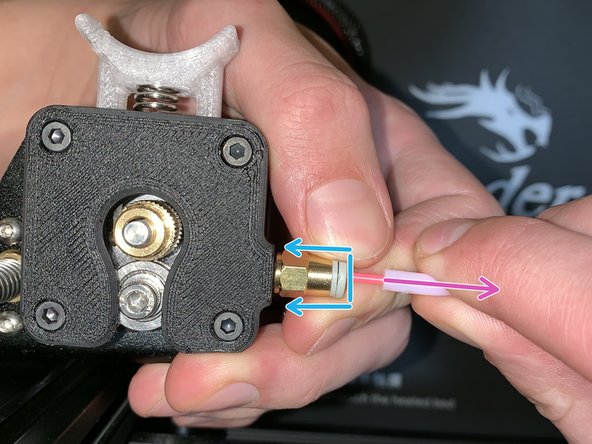

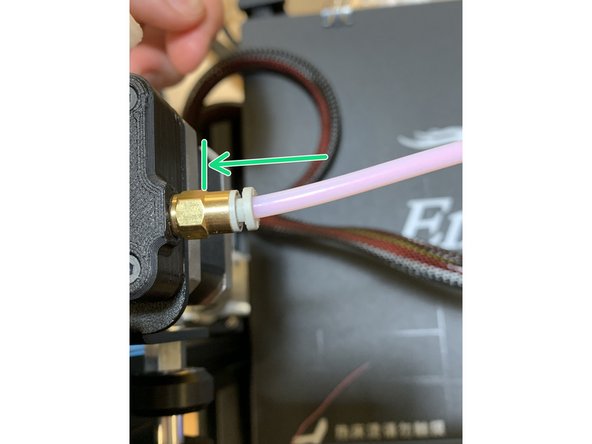

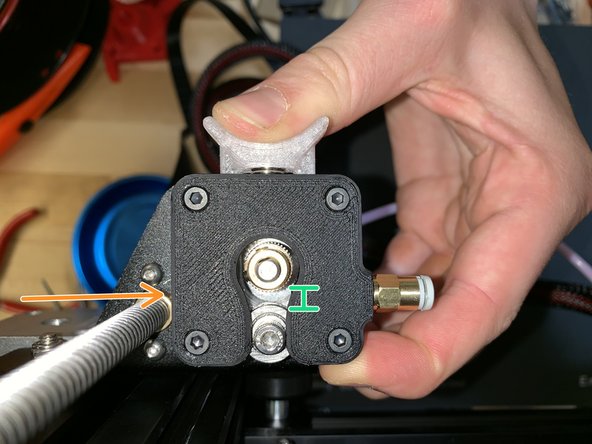

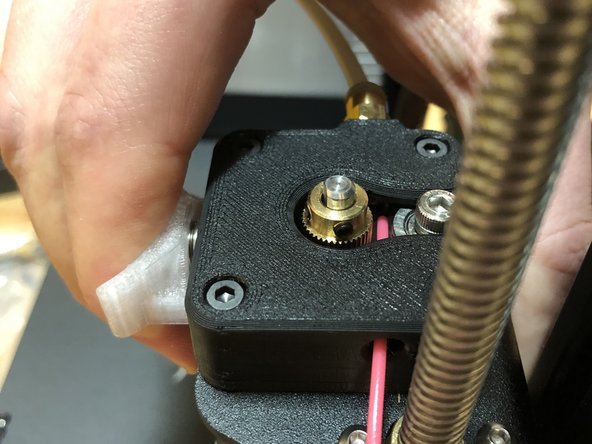

Press back on spring-loaded extruder handle.

-

This will make a gap in between the bearing and the extruder gear.

-

Insert filament from the left side of the extruder mount.

-

It will travel between the bearing and the extruder gear.

-

Push it through the small hole to the right of gear and bearing. This will be the trickiest part.

-

Continue pushing into the white tube until the filament is pressed against the nozzle.

-

If you look closely, you can watch most colors of filament travel through the white tube and towards the nozzle.

-

-

-

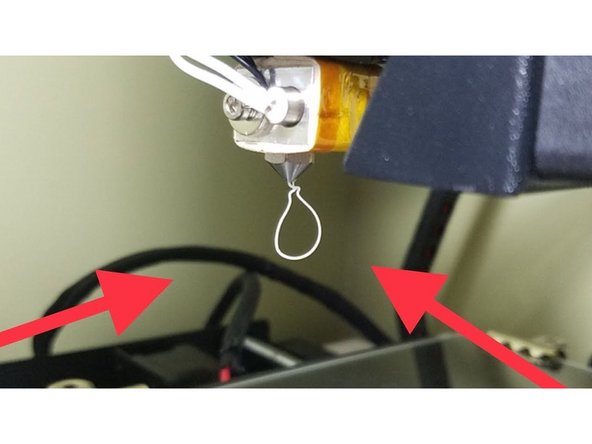

Make sure that your nozzle is at least a few centimeters off of the print bed before this step.

-

Click once on the dial to open the menu.

-

Select Prepare.

-

Select Move Axis.

-

Select Extruder.

-

Select 1 mm.

-

Turn dial clockwise and select ~20 mm by pressing in on the dial.

-

-

-

Your filament is clean and straight! Start your print.

-

Your filament is curling. Check out the blocked nozzle section of our 3D Printer Maintenance Practices.

-

If the previous color does not fully purge.

-

You may just have more filament left in the hottend. Just keep feeding material through.

-

You might have to disassemble the hottend to remove a gap between the PTFE (or heat break) and the nozzle inside of the heater block. Properly reassemble the hottend as shown here.

-

New filament should be loaded

New filament should be loaded

Cancel: I did not complete this guide.

One other person completed this guide.