-

-

Rip cutting means you are cutting along the grain.

-

Cross cutting means you are cutting across the grain.

-

Think of wood as a bundle of straws. If we look at the end grain of wood under magnification this is exactly what we would see. These straws can be large (open grain wood species) or small (closed grain). As you would imagine they exhibit different traits when being cut. These straws are how the tree transports water and nutrients.

-

When rip cutting a lot of stress is relieved from the wood. The wood has grown in the wild, every tree has its own genetic programming, there are a lot of forces that are being resisted every day: soil movement, gravities effect on tree limbs; which changes based on humidity, fruit bearing, wind, and rain.

-

The growth of a tree is dependent on soil, groundwater rain fall, mineralogy etc. The point of this is that the growth of a tree is very complex and all of that translates into the wood product.

-

Left Image: White oak end grain at 7x magnification: we can see the ends of the “straws” clearly. The vertical patterning is formed by growth rings, each separate layer of very porous and less porous layers signifies summer and winter growth. The horizontal patterning is caused by ray cells.

-

Middle Image: Cherry end grain at 7x magnification:the alignments are the same on these two boards. The horizontal pattern you see here is actually due to my loupe, cherry has very few ray cells. Cherry is a close grain wood and you can clearly see the differences

-

Right Image:: 1x view of white oak for reference

-

-

-

As stress is relieved from one area of the wood (ripping a section off) it will bend and move, sometimes instantly and sometimes taking a couple of weeks. This is usually easier to see in a long board but it can happen to any extent on any length of wood (no two boards are alike, some species and sections of a tree are more prone to this).

-

Cross cutting tends to cause less movement in the wood, it is self stabilizing. However the wood is much more resistant to cutting in this direction. The blade must sever each fiber, and the fiber bonds which are quite strong. There is a lot more torque being applied to the wood.

-

Left Image: White oak edge grain at 7x magnification: we can see where a rip cut has severed a few of the fibers but left most in tact. We can also see that the “straws” aren't straight. Their organic shape is what gives wood its unique patterning

-

Middle Image: Cherry edge grain at 7x magnification: Again the difference in grain size and structure is very noticeable

-

Right Image: 1x view of white oak for reference

-

-

-

Why is kickback such a big deal? A table saw is a very powerful tool with the ability to allow you to do an immense amount of work very quickly. This is not intended to dissuade you from using it, but to give some guidance about how to take steps for the sake of your own safety. We have never had an incident in our shop, let’s keep it that way.

-

The labs main wood saw is a Sawstop 10”. The blade spins at 4000rpm, a little math tells us the tip of the blade is moving at 2000 inches per second. Lets assume worst case scenario for a moment: The board we are cutting is 10 lb (this is actually a bit light, an 8ft 2x4 is ~17lbs), and it accepts the full force of the blade.

-

The board will now be moving toward you at approximately 113 mph. That 10 lb board will hit you will a force of over 1500 lbs, approximately 4x the kinetic energy of a police issue 9mm.

-

In addition it is going to try to pull your hands and body into the blade if you are behind the front of the blade. These speeds are are well beyond the limits of human reaction time.

-

-

-

Heat: A build-up of sap on the blades, dullness, very high feed rates and free-handing can cause the blade to overheat, which will make it warp and catch.

-

Pinch and twist: As the wood relieves stress and moves it can pinch the blade.

-

Attempting to free hand cut on the table saw: NEVER free hand cut on the table saw, thats what the bandsaw is for.

-

Wet wood will put a great deal of friction on the blade.

-

Boards that are too short to be properly stabilized by the guides.

-

Warped or twisted wood or any board that does not have at least 2 flat sides. Any board that isn’t straight or is rough cut must be put through the planar and jointer prior to being processed with the table saw.

-

Fatigue and ignorance are the two main causes of accidents in the shop. Add complacency to this list and you will probably have covered 99% of the causes of bad things in any type of shop.

-

-

-

Now that we have a little understanding of what kickback is, why it is so bad, and what causes it: how is it prevented? The short answer is: easily.

-

First and foremost: stand off to the side of the piece you are cutting, never directly behind it. Ensure no one else is behind it either.

-

Second: always ensure the longest side of the wood is supported with a guide. If a narrow face is against the guide your using the wrong one!

-

Heat: The saw blade is checked routinely to ensure it is clean, sharp and free of cracks. Ensure the dust collection is turned on as this keeps additional air passing over the blade, don’t race to complete your cuts. Move the wood at a consistent speed and quickly enough not to burn it, but don't rush.

-

Pinch and twist: You can't predict how the wood is going to react to a cut. Instead ensure the riving knife (splitter) is in place at all times. There are some cuts that require its removal but a shop worker will help you. The saw is set up with 0.020” offset from the front of the blade to the rear, this minimizes surface contact with the board.

-

Use the correct guide or jig for the cut you are making, never use more than one guide! If you aren't sure just ask a shop worker.

-

Attempting to free hand cut on the table saw: NEVER free hand cut on the table saw. I cannot emphasize this enough.

-

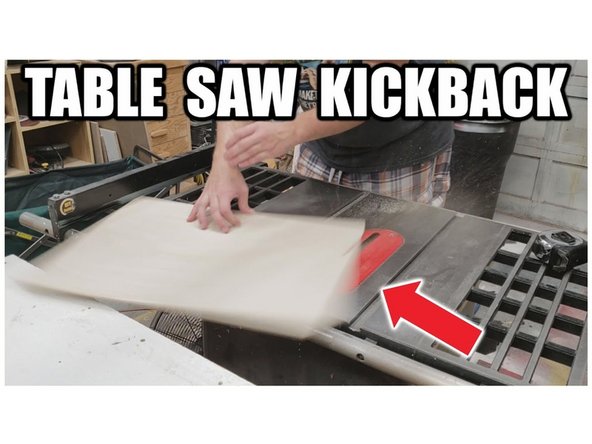

Image: Not OK! “Youtubers” are often idiots and demonstrate improper safety practices. This board should have been cut on a crosscut sled or with a miter gauge. The short side is supported: it would take very little for the operator to twist this board and shoot it back at him.

-

-

-

Wet wood should never be processed in our shop, besides the kickback hazards it also risks setting off the saw stop mechanism ($150). This also means don’t process pressure treated wood in the woods lab!

-

Boards that are too short: never cut a board that doesnt have at least 12” flat against a guide.

-

Warped or twisted wood Inspect any board you are going to put through the table saw. If it is out of shape correct it first.

-

Angled cuts: If you have the blade tipped at an angle the fence needs to be to the side with the greater angle. Passing a board under and angle and into the fence invites binding.

-

Fatigue/inhibited Do not come into the shop sleep deprived or under the influence of any drug or alcohol. If you come into the shop and are suspected of being under the influence campus police will be called to escort you out.

-

Ignorance If you aren't familiar with a tool or are even a little unsure ask questions! Check your teaching sources, not everyone that demo’s woodworking should be. The final thing to be aware of is complacency. Hopefully knowing about kickback will keep you leery of it.

-

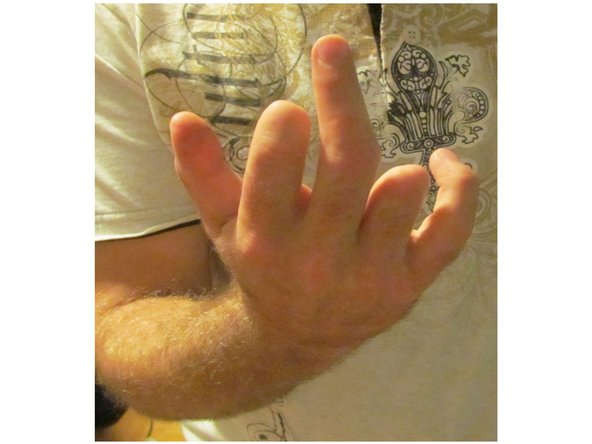

Left Image: Not OK! Salesmen are often idiots and demonstrate improper safety practices. If this board kicks back it is going straight through his dome, no do over, no retry, no more making for that guy. He is also pinching the board into the blade. Never put any pressure in from the side on the “red zone” of the table saw.

-

Right: Not OK! Forum “experts” often demonstrate improper safety practices. Using the miter gauge is right, I am sure destroying it and blade made a great photo. If he was wearing PPE he should be fine. What is dangerous is the board being against the fence. With the board on the miter gauge the fence causes resistance and will force it to twist.

-

Almost done!

Finish Line